1. Understand the Blade Types and Materials

Choosing the right saw blade material is key to ensuring precise cutting. Different materials are suitable for different tasks, and understanding these differences can help you make an informed choice:

High Carbon Steel (HCS): Suitable for softwoods and soft materials such as cardboard and plastics. Although they provide a smooth surface during cutting, they are less durable and are not suitable for cutting metal or hard wood. Their advantages are low cost and suitability for common DIY projects.

Bi-Metal (BIM): Bi-Metal saw blades are made of a combination of high-speed steel and carbon steel, suitable for cutting wood, metal and plastic. Compared with high-carbon steel saw blades, bi-metal saw blades are more durable and can withstand higher pressures, ensuring more precise cutting, especially for work that requires high precision.

Tungsten Carbide (Carbide): This saw blade is suitable for cutting hard materials such as hardwood, tile, plaster and concrete. Carbide saw blades can stay sharp and provide precise cuts on hard materials.

Choosing the right material can ensure that your saw blade performs best for a specific task, especially when it comes to precision cutting, choosing the right material is crucial.

2. Choose the Right Blade Tooth Configuration

The tooth design of a saw blade directly affects the precision and quality of the cut. For precision cutting, choosing the right tooth configuration can help you achieve smoother, clean cuts. Common tooth configurations are:

Fine-toothed blades: These blades are suitable for fine cutting of wood, metal, and plastic. The fine tooth design helps reduce vibration during cutting, avoids burrs during cutting, and enables precise cutting of smaller objects. They are ideal for jobs that require high precision and smooth surfaces.

Segmented blades: These blades have teeth distributed on the outer edge of the blade and are suitable for wood, drywall, and other soft materials. They help make precise cuts in smaller spaces, especially for cutting details or edges.

Diamond blades: Suitable for cutting hard materials such as tile, stone, and concrete. The diamond coating ensures that the blade can make high-precision cuts on hard surfaces with very little wear.

Choosing the right tooth configuration can enable you to achieve the best results when cutting precision.

3. Blade Size and Compatibility

The size of the saw blade and its compatibility with the tool are another important factor in choosing the right saw blade. Most oscillating multi-tools can use saw blades of different sizes, but make sure they match the tool's connection system. The standard sizes are usually:

Blade diameter: Oscillating multi-tool saw blades usually have a diameter between 1 inch and 3 inches. If you need to cut accurately, it will be more appropriate to choose a smaller diameter saw blade.

Universal fit: Many saw blades are designed to be universal fit, meaning they are compatible with multiple brands of oscillating tools. When purchasing, make sure the mounting holes of the saw blade match the tool's connection system.

Ensuring the compatibility of the saw blade with the tool not only improves cutting accuracy, but also ensures safety during use.

4. Cutting Speed and Oscillation Angle

The oscillation angle of the oscillating tool (usually 3° to 5°) has a direct impact on cutting efficiency and accuracy. Generally speaking, a larger oscillation angle can provide faster and more efficient cutting, but may sacrifice the fineness of the cut. Therefore, when making fine cuts, a smaller vibration angle, such as 3°, should be selected to maintain a smoother and more precise cut.

The cutting speed of the vibrating tool will also affect the precision. Some tools allow users to adjust the speed according to different materials, which can avoid excessive speeds causing uneven cutting surfaces or cracks. Using the right speed and vibration angle can not only improve the cutting effect, but also extend the life of the saw blade.

5. Material Compatibility for Precision

Different materials require different saw blades for precise cutting. Choosing the right saw blade can not only improve work efficiency, but also ensure the accuracy of cutting. The following are some recommended saw blade types for common materials:

Wood: For precise cutting of wood, it is best to choose a fine-toothed saw blade (such as high carbon steel or bimetallic saw blades). These saw blades can provide smoother and clean cuts and are not prone to burrs.

Metal: For cutting metals, bimetallic or tungsten steel alloy saw blades work best. They can provide longer life on metal surfaces and can cut accurately without becoming blunt easily.

Tile and Stone: When cutting hard materials, choosing a diamond-coated blade can provide very high precision and avoid cracking or chipping of the material.

Plastic and PVC: For these materials, choosing a high-carbon steel or bi-metal blade with fine teeth can avoid cracking or deformation during the cutting process.

6. Review Blade Features for Added Precision

Choosing a blade with added precision features can further improve cutting accuracy. For example:

Thin Kerf: The thin kerf design reduces the loss of cut material during the cutting process, making the cut more precise and suitable for tasks that require high precision.

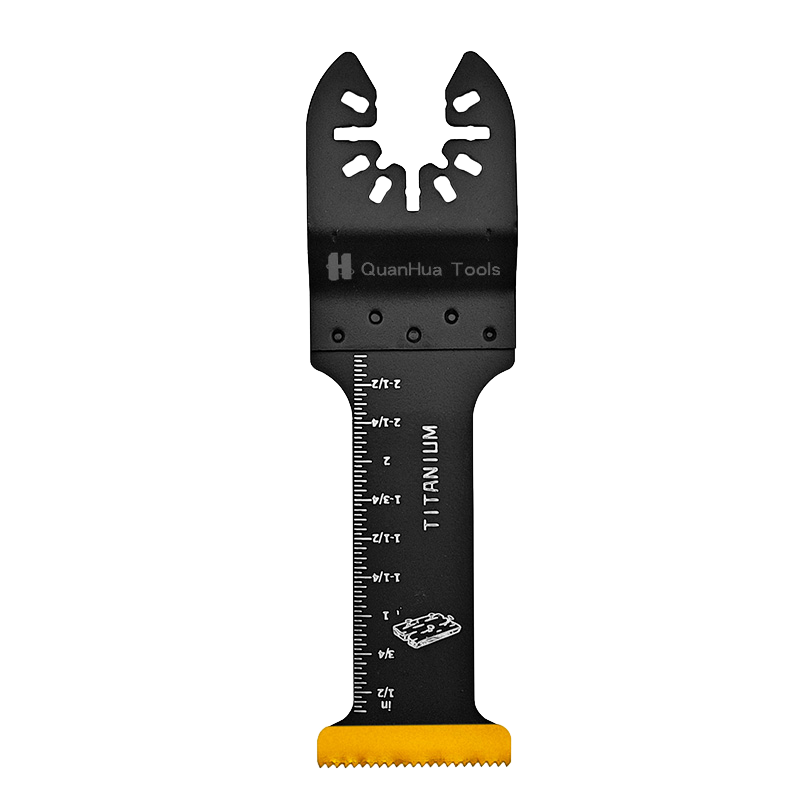

Platinum or Titanium Coating: This coating can reduce friction, increase the life of the saw blade, and help smooth the cut and avoid irregular edges during the cutting process.

Thickened Blade Design: The thickened design provides better support and reduces vibration, resulting in a smoother and more precise result during the cutting process.