What Is an Oscillating Saw Blade and How Does It Work?

An oscillating saw blade is an essential tool in the world of home improvement, woodworking, and even industrial applications. It uses a unique side-to-side oscillating motion rather than a rotary action to cut through various materials. This makes it a versatile tool for performing cuts in tight spaces and on delicate materials.

What Is Oscillating Motion?

Unlike traditional saws that rotate in a continuous circular motion, oscillating tools move back and forth in a side-to-side motion. This rapid, oscillating movement allows the blade to make quick, controlled cuts. The oscillating saw blades are generally mounted on oscillating multi-tools, which can be equipped with various accessories like sanding pads, scrapers, and of course, saw blades.

The oscillating action minimizes vibration and provides greater control, which is particularly useful in precision cutting. This makes oscillating saw blades ideal for small, intricate tasks that require accuracy. The compact nature of the oscillating tool also allows users to work in tight corners or alongside other surfaces where traditional power tools may not fit.

Key Components of an Oscillating Saw Blade

An oscillating saw blade consists of several components, which work together to ensure efficient cutting:

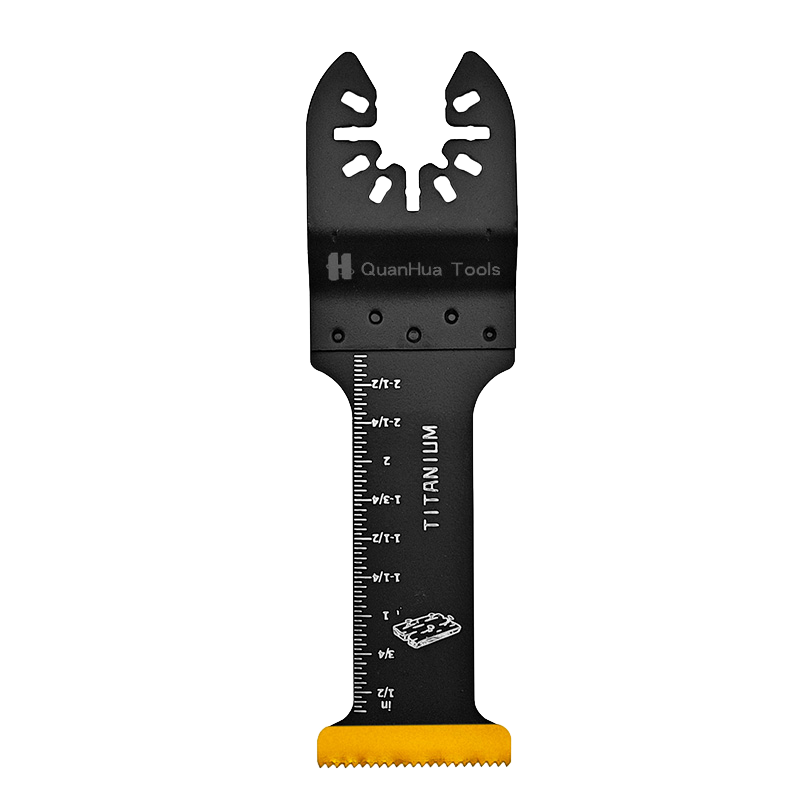

- The Blade: The blade itself can be made of different materials like high-carbon steel, carbide, or bi-metal. These materials are chosen based on the type of cuts they will perform and the materials they will cut through.

- The Teeth: Oscillating saw blades have teeth designed to cut through specific materials. The teeth may vary in size, shape, and material, depending on whether they are designed for wood, metal, or plastic.

- The Mounting Mechanism: The blade is attached to the oscillating tool through a universal attachment system. This system allows the user to quickly change the blades for different tasks.

How Does the Oscillating Saw Blade Work?

The oscillating blade works by attaching to an oscillating multi-tool. The tool uses a motor to drive the oscillating movement of the blade, typically at a frequency of about 20,000 to 30,000 oscillations per minute. When activated, the tool moves the blade rapidly back and forth, allowing it to cut through various materials with minimal friction.

The precision of the cut is determined by several factors, including:

- Blade Type: Blades for wood cutting are different from those used for metal or grout, for example.

- Speed Settings: Many oscillating tools allow users to adjust the speed of the oscillating motion, giving them control over the cutting process.

How to Choose the Best Oscillating Saw Blade for Your DIY Projects?

When selecting an oscillating saw blade, it’s crucial to consider several factors that can influence the performance of your cuts. Different types of saw blades are designed for specific materials and cutting styles. Here’s how to choose the best one for your needs.

Material Compatibility

The first thing to consider is the material you’ll be cutting. Oscillating blades come in different designs to suit specific materials:

- Wood Blades: These blades are typically made of high-carbon steel, which allows for fast cutting without excessive wear. The teeth are designed to make smooth cuts in wood, laminate, or plywood.

- Metal Blades: Blades designed for cutting metal are made from bi-metal or carbide-tipped materials. These blades have stronger teeth capable of cutting through tougher materials like aluminum, steel, and copper.

- Tile/Grout Blades: For cutting tile or removing grout, oscillating blades with carbide teeth are ideal. These blades can handle the hardness of ceramic or stone materials.

Blade Size and Shape

Oscillating blades come in various shapes and sizes, each designed for different cutting tasks:

- Standard Blades: These are general-purpose blades ideal for most tasks. They can be used for wood, plastic, and some soft metals.

- Flush Cut Blades: These blades are flat on one side and are used for cutting materials flush with a surface, such as cutting door jambs or pipes flush against walls.

- Segmented Blades: These are ideal for making aggressive cuts through tougher materials like metal or stone.

Cutting Depth and Precision

Some oscillating saw blades are designed for precise, shallow cuts, while others are intended for deeper, more aggressive cuts. If your project requires intricate or fine cuts, you might opt for thinner, smaller blades. For deeper cuts, a larger or more powerful blade might be needed.

Quality of the Blade

The quality of the blade can affect both the lifespan of the tool and the finish of your cut. High-quality blades tend to have sharper, more durable teeth that resist wear over time. Additionally, they make cleaner cuts with fewer imperfections.

Are Oscillating Saw Blades Suitable for Cutting Wood, Metal, and Plastic?

Oscillating saw blades are incredibly versatile, but their performance varies based on the material being cut. Let’s take a closer look at how oscillating blades perform when cutting wood, metal, and plastic.

Wood Cutting

Oscillating blades designed for wood cutting are incredibly efficient. The fine-toothed blades can make precise, smooth cuts in materials like plywood, MDF, and softwoods. For rough cuts or demolition work, you can also find coarse-toothed blades that can quickly rip through timber. However, the cutting depth is somewhat limited compared to larger saws, so for deep cuts, a circular saw might be more suitable.

Pros:

- Great for precision cutting and trimming

- Ideal for cutting in tight spaces

- Minimal dust and debris

Cons:

- Limited cutting depth

- Not ideal for long, straight cuts

Metal Cutting

When it comes to cutting metal, oscillating saw blades excel, especially when cutting through thin metals like sheet metal, pipes, or small fasteners. Metal-cutting blades are typically made from bi-metal or carbide, materials that are durable and resistant to heat buildup during cutting.

Pros:

- Suitable for cutting thin metals or pipes

- Provides clean, precise cuts

- Great for cutting in hard-to-reach spaces

Cons:

- Not effective for thick or heavy-duty metal

- Cutting through metal generates heat, which can dull the blade faster

Plastic Cutting

Oscillating saw blades also perform well when cutting plastic. The sharp teeth can cut through PVC pipes, acrylic, or even some softer plastics with ease. The key is choosing the right blade, as some plastics can melt if the cut generates too much heat.

Pros:

- Excellent for detailed plastic work

- Clean, smooth cuts

- No distortion or melting

Cons:

- Not ideal for very thick plastic

- The risk of heat buildup when cutting thicker plastic

Comparison of Oscillating Saw Blades for Different Materials

| Material | Recommended Blade Type | Blade Material | Pros | Cons |

|---|---|---|---|---|

| Wood | Standard Tooth, Segmented Blade | High-Carbon Steel | Smooth, fast cuts in softwoods and plywood | Limited depth of cut |

| Metal | Bi-Metal, Carbide-Tipped Blades | Bi-metal/Carbide | Durable, clean cuts in thin metal and pipes | Not for thick metal |

| Plastic | Fine Tooth Blades | High-Carbon Steel | Clean cuts in PVC and acrylic | Risk of melting in thicker plastic |