What Is an Oscillating Saw Blade?

Definition of an Oscillating Saw Blade

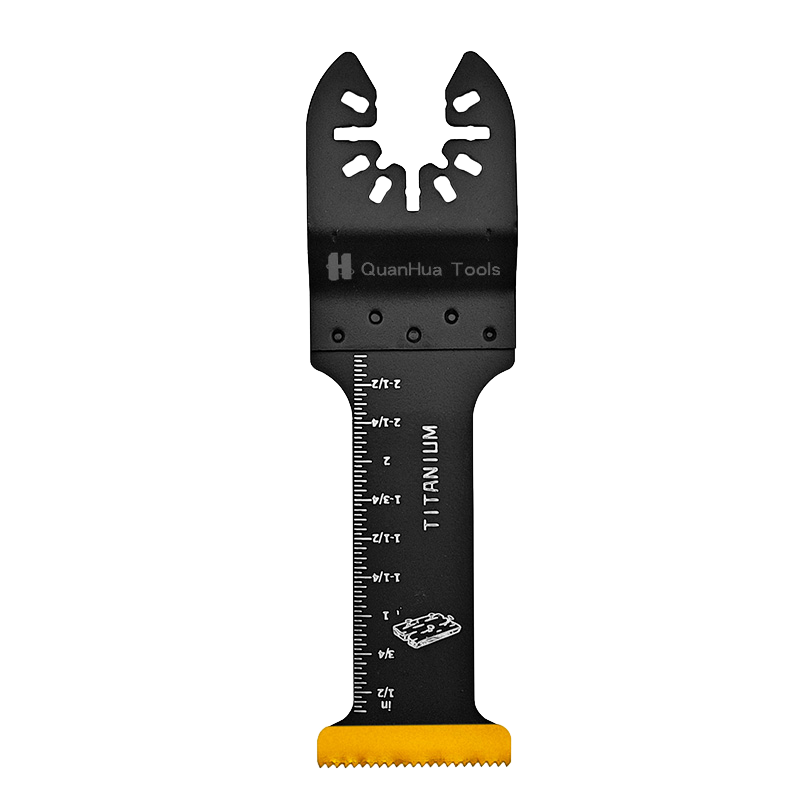

An oscillating saw blade is a specialized cutting tool designed to perform precise cuts through a variety of materials by moving in a rapid, oscillating motion rather than spinning like a traditional saw blade. This type of blade is commonly used with multi-tools or oscillating tools, which are highly versatile and suitable for woodworking, metalworking, plastic cutting, and even renovation projects at home.Types of Oscillating Saw Blades

Oscillating saw blades come in various types depending on the materials and applications they are intended for: - Wood cutting blades:Designed to cut soft or hardwood, often with tooth patterns optimized for fast and smooth cuts. - Metal cutting blades:Typically made of bi-metal or high-speed steel to cut through aluminum, steel, or other metals. - Multi-material blades:Can handle wood, plastic, and thin metals, providing flexibility for different projects. Specialty blades:Such as grout removal, plunge cutting, or sanding attachments.

Common Shapes and Sizes

Oscillating blades come in different shapes to suit various tasks: Semi-circular blades: Ideal for curved cuts and flush cutting. Rectangular or straight blades:** Suitable for plunge cuts and straight-edge cuts. Triangular sanding attachments:Used for sanding in corners and edges.Common Oscillating Saw Blade Types and Uses

| Blade Type | Material Compatibility | Common Uses |

|---|---|---|

| Wood Blade | Softwood, Hardwood | Furniture, Carpentry |

| Metal Blade | Aluminum, Steel, Copper | Pipes, Metal Sheets |

| Multi-Material Blade | Wood, Plastic, Thin Metal | Home Renovation, DIY Projects |

| Specialty Blade | Tile, Grout, Drywall | Cutting Tiles, Removing Grout |

How Does an Oscillating Saw Blade Work?

The Oscillation Mechanism

Unlike circular saws or jigsaws, an oscillating saw blade moves in a rapid side-to-side motion at a high frequency. This oscillation allows the blade to make precise cuts without spinning, reducing the risk of slipping or damaging the material. The tool’s motor drives the oscillation, often between 10,000 to 20,000 oscillations per minute, depending on the model.Advantages Over Traditional Saws

Precision:The short, fast motion allows for highly controlled cuts, especially in tight spaces. Reduced vibration:Less stress on the user’s hands and more accurate results. Versatility:Works well on materials that traditional circular or reciprocating saws struggle with.Ideal Scenarios for Oscillating Blades

Cutting inside corners or against walls where space is limited. Making plunge cuts directly into wood, plastic, or metal. Trimming or sanding in tight areas without removing surrounding structures.Key Benefits of Using an Oscillating Saw Blade

Precision and Control

One of the most significant benefits of an oscillating saw blade is its precision. Because the blade does not rotate but oscillates in place, users can make clean, accurate cuts without damaging adjacent surfaces. This is particularly useful for trimming door jambs, cutting flooring, or modifying furniture pieces.Versatility Across Materials

A single oscillating tool can accommodate multiple blade types, allowing it to cut wood, metal, plastic, and tiles. This multi-material capability reduces the need for multiple tools, saving both time and money.Safety and Convenience

Reduced kickback:The oscillating motion prevents the tool from jerking unexpectedly. Compact design:Easy to use in confined spaces or awkward angles. Reduced material waste:** Precision cuts reduce errors, minimizing wasted materials.Common Applications of Oscillating Saw Blades

Woodworking

Oscillating blades are frequently used in carpentry for cutting trims, molding, and small wooden components. Their ability to plunge cut allows precise notches and adjustments without damaging larger wooden panels.Metalworking

Bi-metal or high-speed steel blades can cut through aluminum sheets, steel pipes, or copper rods efficiently. While slower than specialized metal saws, the oscillating tool provides precision in small or awkward spaces.Home Renovation and DIY Projects

Oscillating saw blades are perfect for tasks such as: Removing grout between tiles Cutting drywall - Trimming doors or cabinets - Making custom cuts in laminate or vinyl flooringOther Uses

Cutting PVC pipes Removing old caulk - Sanding corners with triangular attachmentsTips for Choosing the Right Oscillating Saw Blade

Material Compatibility

Wood: High-carbon steel blades or specialty wood blades Metal:Bi-metal blades for durability Tile/Hard Surfaces: Carbide-grit bladesBlade Shape and Design

Choose the shape based on your task: Semi-circular for precision cuts and flush trimming Rectangular for plunge cuts and long straight cuts - Triangular for sanding cornersBlade Longevity

High-quality blades last longer and resist wear. Avoid using wood blades on metal or abrasive materials to prevent damage. Store blades in a dry, protected environment to prevent rust.Compatibility With Multi-Tools

Most modern oscillating blades are universal, but always check compatibility with your specific tool brand. - Some brands offer quick-release adapters for faster blade changes.Understanding what an oscillating saw blade is and how it works is essential for anyone looking to improve their DIY, woodworking, or renovation projects. Oscillating blades provide precision, versatility, and safety, making them a valuable addition to any toolbox. Choosing the right blade for the material, task, and tool ensures maximum efficiency and longer blade life.

By selecting quality oscillating saw blades and using them correctly, you can tackle wood, metal, plastic, and tile projects with confidence and achieve professional results every time.