When it comes to cutting wood, metal, plastic, and other materials, sabre saw blades and jigsaw blades are often used interchangeably due to their similar appearance and functionality. However, they have key differences in terms of performance, capabilities, and ideal use cases. Understanding these differences can help you choose the right tool for your project.

1. Overview of Sabre Saw Blades

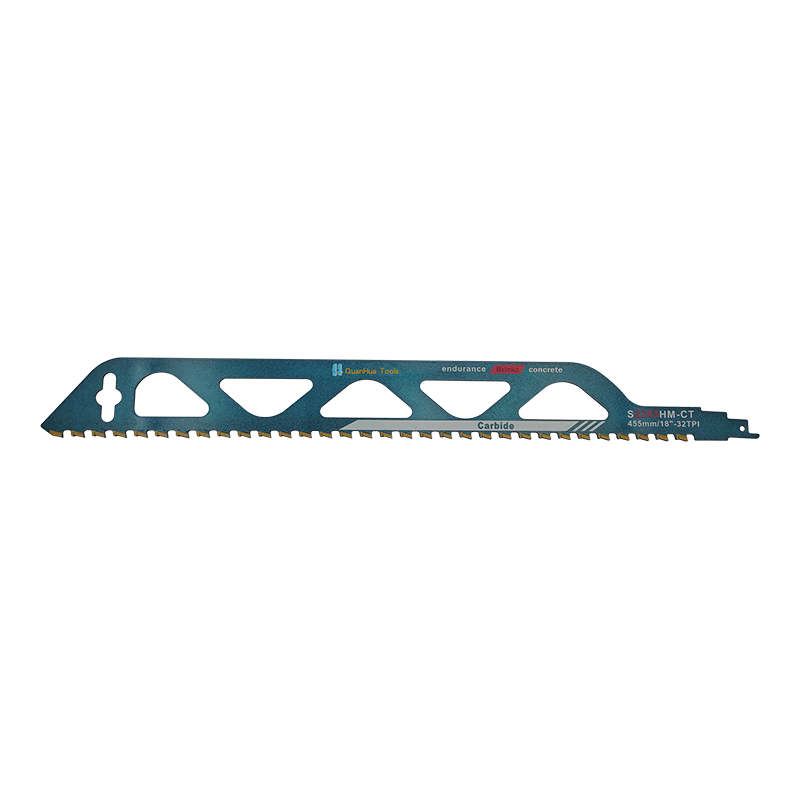

A sabre saw (also known as a reciprocating saw) is a powerful, heavy-duty tool commonly used for demolition, rough cuts, and heavy-duty construction tasks. The sabre saw features a long, straight blade that moves back and forth in a quick, reciprocating motion. It is typically used for cutting through larger, thicker materials, making it an essential tool for construction and demolition work.

Key Features of Sabre Saw Blades:

- Longer Stroke Length: Compared to other saws, sabre saw blades have a longer stroke, allowing them to cut through thicker materials more efficiently.

- Variety of Blade Types: Sabre saw blades come in various lengths, thicknesses, and tooth configurations, making them suitable for different tasks, such as cutting wood, metal, and plastic.

- Aggressive Cuts: The longer stroke length and fast reciprocation allow for more aggressive cutting, making them ideal for demolition or quick cuts on larger materials.

Common Types of Sabre Saw Blades:

| Blade Type | Suitable Materials | Features |

|---|---|---|

| Wood Blades | Wood, Plywood, Composites | Fast, rough cuts, ideal for demolition |

| Metal Blades | Steel, Iron, Copper, Aluminum | Durable for cutting metal |

| Demolition Blades | Drywall, Insulation Materials | Ideal for demolition work |

2. Overview of Jigsaw Blades

A jigsaw is a smaller, more precise tool designed for detailed cutting work. It is commonly used for tasks requiring intricate, curved, or straight cuts, such as woodworking, crafting, and construction. Jigsaws use a short blade that moves in a rapid up-and-down motion, and their high control and precision make them ideal for fine, detailed work.

Key Features of Jigsaw Blades:

- Shorter Stroke Length: Compared to sabre saws, jigsaw blades have a shorter stroke, allowing them to cut in a more controlled manner, making them perfect for detailed tasks.

- Precision and Detail: Jigsaws excel at making highly precise cuts, especially for curves, straight lines, and bevels.

- Compact Design: Jigsaws are typically smaller and lighter than sabre saws, making them easy to maneuver in tight spaces and perfect for intricate cutting tasks.

Common Types of Jigsaw Blades:

| Blade Type | Suitable Materials | Features |

|---|---|---|

| Wood Blades | Wood, Plywood, Composites | Ideal for fine, curved cuts |

| Metal Blades | Steel, Aluminum, Copper, Iron | Suitable for cutting thin metals |

| Tile Blades | Ceramic, Stone | Fine cutting, prevents cracking |

3. Cutting Performance Comparison

Speed and Efficiency

Sabre Saw Blades:

- Speed and Efficiency: Due to their longer stroke and more powerful motor, sabre saws can quickly cut through thicker and harder materials. They are ideal for demolition work or making fast cuts in larger materials like wood and metal pipes. However, despite their speed, they are generally not suited for tasks requiring high precision.

- Advantages: Quick cutting, especially in thicker materials. For example, when demolishing walls, the sabre saw can efficiently slice through drywall.

Jigsaw Blades:

- Speed and Efficiency: Jigsaw blades cut more slowly compared to sabre saws, but their slower, more controlled cutting action allows for greater precision, making them ideal for tasks where fine cuts are important. While they can handle thicker materials, their cutting efficiency is lower for large, rough cuts.

- Advantages: High precision, ideal for fine cutting tasks, especially for curved or intricate cuts.

Cutting Quality

Sabre Saw Blades:

- Cutting Quality: Due to their more aggressive cutting action, sabre saw blades often leave rougher edges when cutting through materials like wood. Therefore, they are better suited for rough cuts, rather than tasks that require smooth, finished edges.

Jigsaw Blades:

- Cutting Quality: Jigsaws provide smoother and more precise cutting, especially on wood and metal. Their slower cutting motion allows for better control, which results in cleaner edges, making them suitable for detailed work where precision is important.

4. Versatility in Material Cutting

Sabre Saw Blades:

- Material Compatibility: Sabre saw blades can cut through a wide variety of materials, including wood, metal, PVC, and drywall. Due to their longer stroke length, they are better suited for thicker materials like lumber and metal pipes.

Jigsaw Blades:

- Material Compatibility: Jigsaw blades are also versatile and can handle wood, metal, plastic, and ceramic materials. However, due to their slower cutting speed and shorter stroke, they are more suitable for thinner materials. For cutting thick metal or other hard materials, jigsaws are slower and less effective.

5. Blade Types and Their Applications

Sabre Saw Blades:

- Wood Blades: Designed specifically for cutting wood, these blades often have larger teeth for rough, fast cuts.

- Metal Blades: These blades are ideal for cutting through metal pipes or thin metal sheets, often made from bi-metal construction for added durability.

- Demolition Blades: These blades are wider and designed for quick cuts through materials like drywall and plastic pipes.

Jigsaw Blades:

- Wood Blades: These blades are perfect for making precise cuts in wood, and their small teeth are ideal for making curved or fine straight cuts.

- Metal Blades: These blades are designed for cutting metal, suitable for thin sheets or pipes.

- Tile Blades: Specialized blades for cutting ceramic, stone, and other brittle materials.

6. Tool Size and Maneuverability

Sabre Saws:

- Size and Maneuverability: Sabre saws are typically larger and heavier than jigsaws, which can make them harder to maneuver in tight spaces or for intricate cuts. Despite this, they excel in tasks that require more power and speed.

Jigsaws:

- Size and Maneuverability: Jigsaws are compact, lightweight, and easy to control, making them ideal for working in confined spaces. Their smaller size makes them the preferred tool for detailed and delicate cutting tasks.

7.When to Use Which Tool?

Use a Sabre Saw Blade When:

- You need to cut through thicker or tougher materials quickly.

- You are working on a demolition project or other large-scale construction tasks.

- Speed and power are more important than cutting precision.

Use a Jigsaw Blade When:

- You need to make detailed, intricate, or curved cuts.

- Precision and finish quality are important for your project.

- You are working with thinner materials or need to make smooth, accurate cuts.