When it comes to cutting tools, Oscillating Multitool Saw Blades and Reciprocating Saws are two of the most commonly compared tools among DIY enthusiasts and professionals alike. While both tools offer excellent cutting capabilities, their designs, applications, and performance differ in ways that can influence your decision on which one to choose based on your specific project needs.

1. Tool Design and Functionality

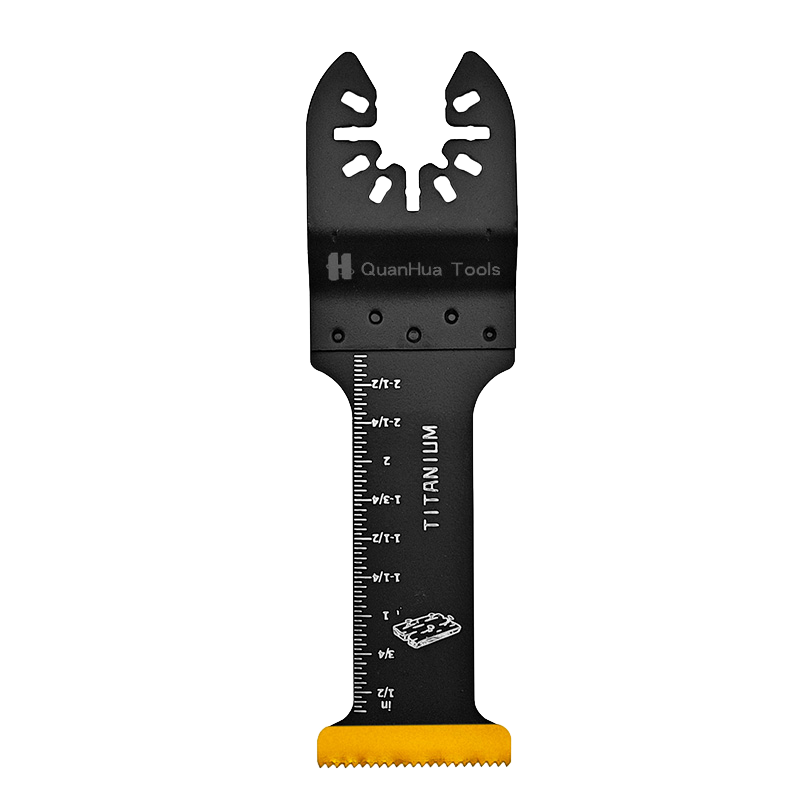

Oscillating Multitool Saw Blades

Oscillating tools are unique and highly versatile, using a vibration (oscillating) motion to perform cutting tasks. Unlike traditional saw blades, the blade doesn’t rotate; instead, it moves back and forth in small arcs. This unique motion allows for more precise cutting, especially for intricate tasks.

- Oscillating Motion: The blade moves in a very small oscillating motion, typically only a few degrees. This allows for more controlled and precise cutting, making it ideal for detailed work, such as cutting along edges, trimming, or cutting in confined spaces.

- Compact Design: Oscillating tools are typically small and lightweight, making them suitable for tight spaces and hard-to-reach areas.

- Versatility: Not only are oscillating tools used for cutting, but they can also perform other tasks like sanding, scraping, grout removal, and more, making them a multi-functional tool.

Reciprocating Saws

Reciprocating saws are powerful, heavy-duty cutting tools that operate with a back-and-forth motion of the blade. Unlike oscillating tools, reciprocating saws are designed for fast, rough cuts and are ideal for larger, more aggressive projects.

- Reciprocating Motion: The blade moves back and forth in a straight line at a high speed. This rapid motion allows for fast cutting through a variety of materials, particularly thick or heavy-duty materials.

- Powerful Design: Reciprocating saws are typically more powerful than oscillating tools, capable of cutting through wood, metal, PVC pipes, and more.

- Bulkier Build: Reciprocating saws are generally larger and heavier than oscillating tools, making them less suitable for precision cutting but ideal for heavy-duty cutting tasks.

2. Cutting Capabilities

Oscillating Multitool Saw Blades

Oscillating tools are great for precise cutting. Thanks to their small oscillation arc, they offer superior control, making them perfect for detailed or intricate cuts.

- Precision Cutting: Oscillating tools excel in precision cuts, especially when trimming, cutting drywall, or working in tight spaces. They are perfect for tasks that require high accuracy, such as cutting along walls, trimming pipes, or cutting in corners.

- Suitable Materials: Oscillating tools are best for lighter materials such as wood, plastic, drywall, and some thin metals. They may not be as effective for cutting through thicker materials like heavy wood or tough metal.

Reciprocating Saws

Reciprocating saws are built for heavy-duty cutting, making them ideal for rough cuts through thicker materials. The back-and-forth motion is faster and more aggressive, allowing users to cut through tough materials quickly.

- Heavy-Duty Cutting: Reciprocating saws are designed to cut through thicker materials, such as wood, metal, PVC pipes, and even tree branches. They excel in demolition and rough-cutting tasks where speed and power are essential.

- Depth of Cut: Reciprocating saws have longer, more robust blades that can easily handle deep cuts into thick materials, making them perfect for heavy-duty applications.

3. Cutting Speed and Efficiency

Oscillating Multitool Saw Blades

Due to the oscillating motion, these tools are generally slower in cutting compared to reciprocating saws. While they don’t offer the same cutting speed, their precision makes them ideal for more controlled tasks.

- Slower Cutting Speed: Oscillating tools are ideal for detailed work, but their cutting speed is slower compared to reciprocating saws. For thicker materials, you may need to take your time for effective cuts.

- Less Vibration: Since the oscillating motion is minimal, it generates less vibration, offering a more stable and comfortable user experience.

Reciprocating Saws

Reciprocating saws are designed to cut quickly through thicker materials. Their rapid back-and-forth motion and powerful motor make them highly efficient for large, rough cuts.

- Faster Cutting Speed: The high speed and powerful movement of reciprocating saws make them ideal for quick, large cuts, especially in demolition or heavy-duty tasks.

- More Vibration: The rapid motion generates more vibration, which can make it harder to control the saw during precise cuts. Over long periods, the vibration can also lead to more user fatigue.

4. Comfort and Control

Oscillating Multitool Saw Blades

Oscillating tools are generally easier to control due to their compact design and minimal vibration. The controlled oscillating motion allows users to make precise cuts, even in small or awkward spaces.

- Easier to Control: Thanks to their precise motion and smaller size, oscillating tools offer better control, making them ideal for tasks that require accuracy, like cutting along walls, trimming wood, or making plunge cuts.

- Less Vibration and Noise: Oscillating tools produce less vibration and noise, which makes them more comfortable to use for extended periods of time, especially when working on intricate projects.

Reciprocating Saws

Reciprocating saws are heavier and generate more vibration, which can lead to less control and greater fatigue over time. While they offer more power, the added size and vibration make them less ideal for delicate tasks.

- Harder to Control: The high-speed motion of the reciprocating saw makes it less suitable for precise cutting, especially when working in tight spaces or on delicate materials. It requires more effort and control to keep the saw steady during use.

- Increased Fatigue: Due to the vibration and weight, using a reciprocating saw for long periods can cause user fatigue, particularly in extended demolition tasks.

5. Applications

Oscillating Multitool Saw Blades

Oscillating tools are perfect for tasks requiring precision and versatility. They are suitable for a wide range of applications, especially when space is limited or when you need to perform multiple tasks.

- Precision Cutting: Oscillating tools are perfect for cutting detailed pieces, trimming wood, metal, or plastic, and performing fine cuts on small materials.

- Other Functions: Beyond cutting, oscillating tools can also be used for sanding, scraping, grout removal, and other surface preparation tasks, making them an all-in-one solution for various tasks.

Reciprocating Saws

Reciprocating saws are built for demolition and heavy-duty cutting tasks. They are designed for cutting through large pieces of material and are ideal for construction and renovation projects.

- Demolition Work: Reciprocating saws are ideal for demolition tasks like tearing down walls, cutting through pipes, and clearing vegetation. They can handle large, thick materials quickly and efficiently.

- Large-Cut Tasks: If you need to cut through large or tough materials, a reciprocating saw is the right tool for the job. It can handle tasks like cutting lumber, pipes, or metal beams in a short amount of time.

6. Blade Options and Maintenance

Oscillating Multitool Saw Blades

Oscillating tools offer a wide range of blade options, and they are easy to change. These tools typically don’t require specialized equipment for blade replacement, making maintenance relatively simple.

- Wide Range of Blades: Oscillating tools are compatible with various blades, such as wood blades, metal blades, carbide blades, and sanding pads, allowing them to perform multiple functions.

- Blade Maintenance: Blade replacement is simple and can be done without specialized tools. Just keep the blades sharp and clean to ensure efficient cutting.

Reciprocating Saws

Reciprocating saws also offer multiple blade options for different tasks, such as cutting wood, metal, and demolition blades. These tools tend to have stronger blades suited for tougher materials.

- Blade Durability: Reciprocating saw blades are built to withstand heavy-duty cutting, and they last longer compared to oscillating tool blades.

- Blade Maintenance: While blade changes are generally easy, some models may require additional tools for adjustments or blade replacement.

7. Cost Comparison

- Oscillating Tools generally have a lower upfront cost, especially for basic models. However, high-quality replacement blades can add to the cost.

- Reciprocating Saws tend to be more expensive initially, particularly for more powerful models. However, the cost of replacement blades can vary depending on the material and type of cutting blade.