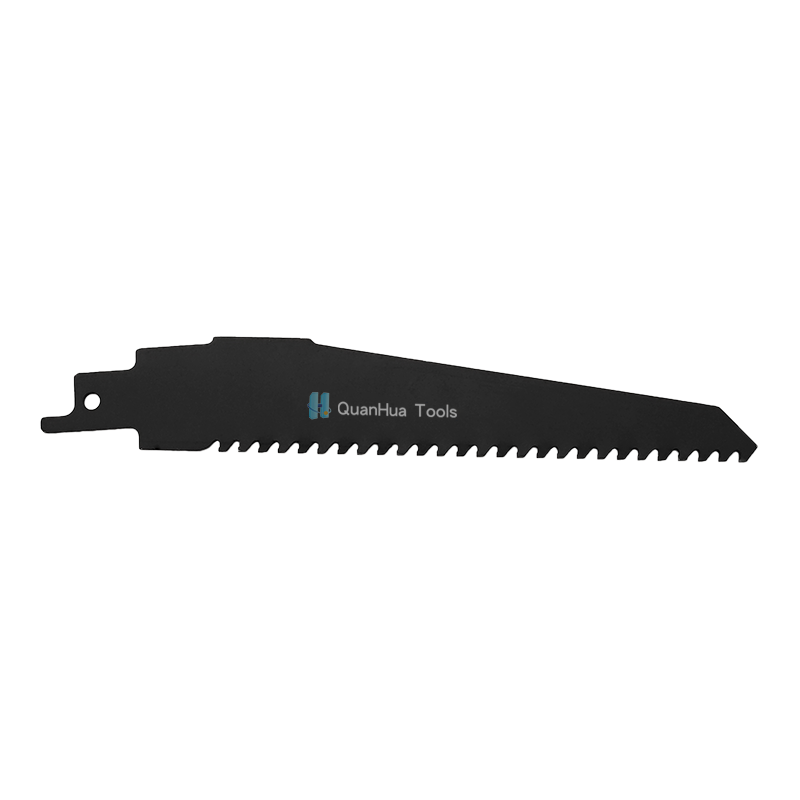

What is a carbide saber blade?

A carbide saber blade is a blade designed for high-intensity cutting, and the teeth or blade surface is usually embedded with hard tungsten carbide particles or teeth. Compared with traditional high carbon steel (HCS) or bi-metal blades, carbide blades have higher hardness, heat resistance and wear resistance.

In oscillating multi-tools, this blade is widely used for a variety of tasks from demolition projects to fine metal cutting. Its unique "saber" design makes it easy to cut metal pipes, nails, screws and even tiles and drywall.

Why choose carbide saw blades? Five reasons

High durability

Carbide is second only to diamond in hardness. Compared with ordinary steel saw blades, carbide saw blades can withstand longer work and are not easy to dull, especially suitable for repetitive or high-intensity tasks. For example, a regular saw blade may fail after cutting a few nails, while a carbide blade can work continuously for hours or even days.

Excellent cutting ability

These blades can cut very hard materials, such as:

Stainless steel

Concrete slabs (such as HardieBacker)

Galvanized screws and nails

Copper pipes and aluminum alloys

Fiberglass reinforced plastic (FRP)

You don't need to frequently change blades of different materials, which saves a lot of time.

More cost-effective

Although the initial price is slightly higher, carbide saw blades have a longer life and are less prone to damage, which saves money overall. They can handle multiple high-intensity tasks that traditional saw blades cannot complete, reducing downtime caused by changing consumables.

One carbide saw blade can handle almost all challenges from wood, metal, plastic to masonry materials. It is an ideal "all-round knife" for renovation or demolition projects with multiple materials.

Faster and cleaner cutting

Carbide saw blades are highly rigid and are not prone to bending, swinging, etc. This results in a more stable cutting process, less burrs and broken edges, and more precise control of the cutting line, which improves the appearance of the final product.

Common Applications

Carbide saber blades are suitable for cutting tasks in a variety of high-intensity and complex environments, including but not limited to:

Bathroom or kitchen demolition projects: cutting wall tiles, cement board, old pipes.

When nails or screws are embedded in wood: no need to worry about damaging the saw blade.

Door frame reconstruction: quickly cut metal door frames or inlays.

Garage or shed renovation: deal with rusted nuts, bolts, aluminum or plastic pipes.

Building cleanup work: easily cut through mixed materials during demolition.